- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Shape: | |

|---|---|

| Direction of magnetisation: | |

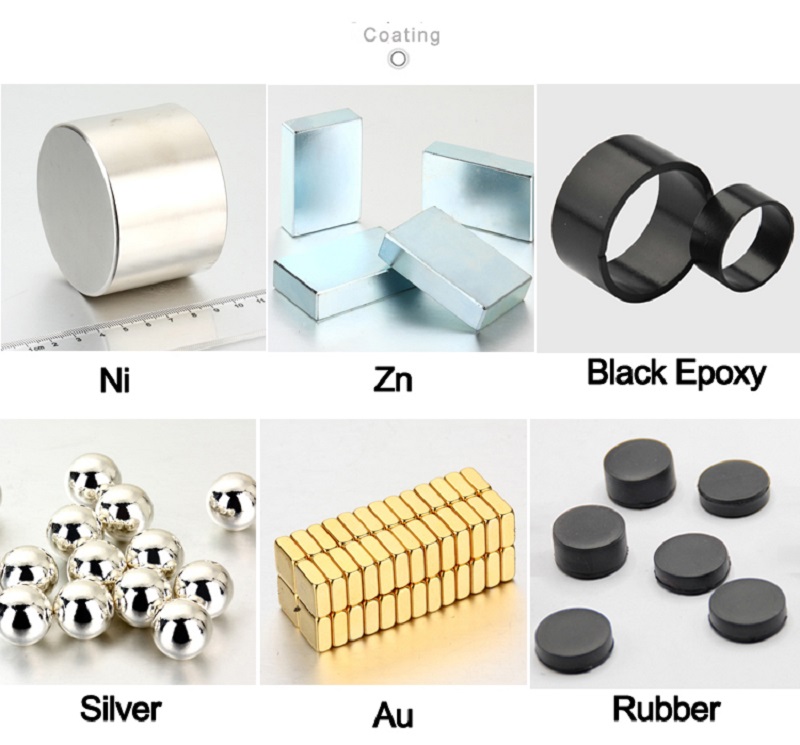

| Type of coating: | |

| grade: | |

| Tolerance in size: | |

| Availability: | |

BWND

BMAG

8505111000

Product Description

With a sintered ndfeb Japan, Germany, the European Union in the patent technologies such as the thawing, our country each big sintering factory of collaborative efforts, sintered ndfeb improve the product grade. As a high-tech applications for its comprehensive performance of the constantly improve, the requirements of the surface treatment of sintered ndfeb also greatly increased, the traditional processing method has been unable to meet the requirements of industrial progress. Electronic science and technology university, sichuan, jiaotong university, red rice and other scientific research institutions, from the microscopic molecular structure, essentially perfect surface treatment principle and industrial application technology development, after four years of hard work and the key technology breakthrough. Nanometer claw (3010)

There is no coating treatment for the composite film, and this technology is an original technological process. The active groups contained in the nano film layer have strong resistance to moisture, oxygen, chlorine ion (Cl), carbon dioxide (CO2), etc. The corrosion resistance and bonding ability of organic resin have been greatly improved. Its excellent surface physical and chemical properties will have a significant impact on the application field.

In December 2013, the process by the sichuan, Chinese Academy of Sciences system test. The corrosion resistance of use 20 to 30 years in the Marine climate condition, can be widely used in wind power heikki. Surface bond strength more than 20 mpa, can be widely used in high-speed permanent magnet motor, special motor, electric car motor, ultra-high voltage, high voltage dc power supply system, a quick charging system, aerospace defense industry and other fields.

Magnetic direction

+86-574-87504597

+86-574-87506697

thomas03@bwmagnet.com